| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Mingrui

Model Number : XF-227

Certification : ISO9001

Place of Origin : China

MOQ : 1pieces

Price : negotiable

Payment Terms : L/C, T/T, Western Union, MoneyGram, D/P, D/A

Supply Ability : 500 pieces per month

Delivery Time : 15 working days after the order confirmed

Packaging Details : international carton box

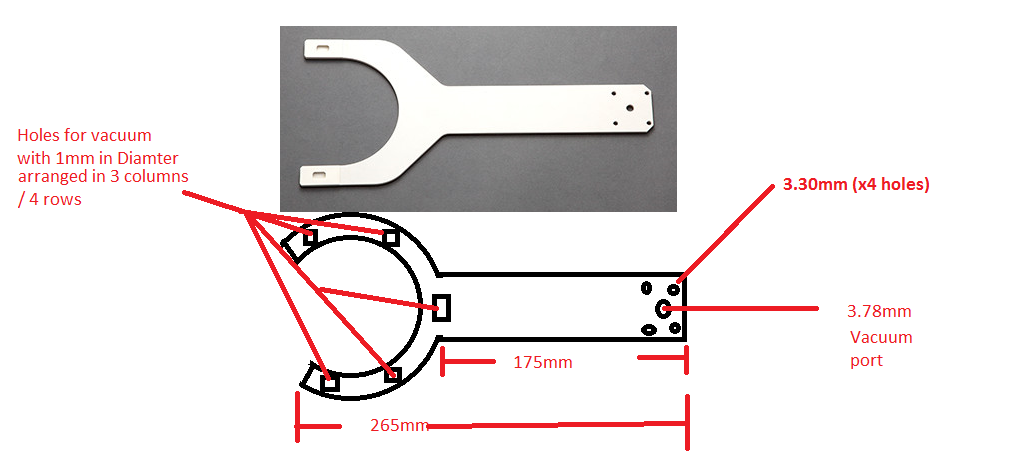

item : Ceramic End Effector

material : Alumina or zirconia

semiconductor : DT-NWH1050DM-TH

Function : Handle wafer

Type : Semiconductor Ceramic

shape : custom

dimension : custom

Finishing : with groove

Port type : Vacuum port

Sample : available

Zirconia Alumina Ceramic End Effector for Handle Wafer with Vacuum Port Semiconductor Ceramic

End effectors constitute the end of the robot arm which handles and moves the semiconductor wafer between positions. It’s basically the robot’s hand so it is important that it be thermally and dimensionally stable and not contaminate the chamber with particles or chemical contaminants.

Ceramic end effectors are used for their stiffness and high strength, meaning the robot arm settles to its final position faster than with aluminium. Additionally, the robot’s motion itself is faster, optimising positioning accuracy and increasing efficiency.

The ceramic material is chosen based on the deposition chemistry to which it will be exposed. For example, if plasma is used, a minimum 99.5% alumina must be used.

The same consideration of gas chemistry is needed for determining the interior materials for plasma etch processes. If an anodised aluminium or alumina chamber is used with fluorinated gases or oxygen plasma then an yttria coating may be used on theanodised aluminium walls to prevent chemical attack. Yttria has superior erosion resistance and low particulation compared with alumina or thermal spray alumina coating.

Mingrui is a leading company producing end effectors such as vacuum chuck end effectors and has met the requirements of our customers.

Please contact us if you are examining how to carry wafers.

Mingrui produces vacuum chuck end effectors which have vacuum lines without bonding layer.

As we can form a built-in Hollow channel which requires no adhesive,our ceramic end effector can be used at high temperature and take advantage of the solution of organic outgasses.

|  | |

| Usually put SUS or aluminum tape on the back side and close the cap | No needs to put SUS or aluminum tape |

| Example of products of Built-in follow channel (Vacuum lines are transparent in the ceramics.) |

Character of ceramic parts :

1. High temperture ceramics -- crucibles , nozzles , lasers , furnace / kiln fixtures

2. wear and corrosion resistant ceramics -- plates, hosings , gages , caps / lids

3. Electrical insulating ceramics --contact blocks , standoffs, fasteners , spacers

4. Good dimension stability , no deformation at any situation

5. beatiful apprearance , never be aged and ocidated .

Industrial Ceramic Intriduction

Aluminium Oxide, Al2O3 is the most widely applied and cost effective technical ceramic material. It offers a combination of superior mechanical strength and electrical properties, wear resistance and corrosion resistance. The maximum working temperature is up to 1700 °C with relatively high thermal conductivity. It is also an electrically insulating material with a high electrical resistivity. The good corrosion resistance makes it insoluble in water and slightly soluble in strong acid and alkaline solution.

Company Introduction

Mingrui ceramic manufacture and provides alumina ceramic components for a wide range of application like Mechanical Equipment, Electronic & Electrical, Oil Drilling, Medical, Chemical Industry etc. According to actual application and customer's requirement, the purities vary from 95%-99.7% and the forming methods will be different. The forming methods applied in our plant include dry pressing, isostatic pressing, injection moulding, extrusion moulding. With experienced engineers and talented workers, we are confident to offer high quality, high precision, complex components for customers worldwide.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have any other question, pls feel free to contact us .

|

|

Industrial Ceramic Products Zirconia Alumina Ceramic End Effector For Carry Wafer Images |